The engine oil cap was forced out of place and engine oil gushed out.

The whole engine was covered with engine oil.

Clearing this mess was a small matter. A bottle of degreaser would do the trick.

This is the broken exhaust valve.

Just some basic knowledge on how a 4-stroke diesel engine work. There are exhaust valves (in charge of discharging exhaust gas) and intake valves (in charge of letting air into the combustion chamber). Below the valves is the piston.

So if the valve broke, it will drop onto the piston. The piston moves up and down the cylinder to compress the air in the combustion chamber against the cylinder head to turn the propeller. In order to access the broken valve, we had to remove the cylinder head which equaled to 'BIG headache'!

Let me try to list out what items we have to remove before we can take out the cylinder head.

1) Air filter

2) Coolant expansion tank

3) Compressor

4) Turbocharger

5) Heat exchanger

6) Intercooler

7) Thermostat

8) Exhaust manifold

9) Numerous oil/fuel/water/air pipes

It took one day to dismantle these items.

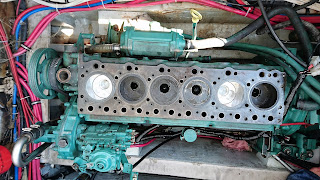

This is where the broken exhaust valve and spring should be.

At last we reached the cylinder head gasket, where we could access the broken valve.

Inspecting the cylinder head for any damage that might be caused by the piston crushing the broken valve onto the head.

The engine looked much smaller when so many parts were taken off.

Luckily there were no damage to the cylinder head. I also made used of this opportunity to check whether any of the pistons and cylinders were damaged. In my previous post on sea trials, there were many cases of engine overheating and one of the overheating incident actually jammed the engine. In case you are wondering how overheating will jam the engine, let me explain briefly here.

Heat will cause metals to expand. When an engine overheat, the piston will expand more than the cylinder surrounding it. When the expansion is more than the clearance between the piston and the cylinder, the piston will be stuck in the cylinder causing the engine to stop instantly. As this happens while the engine is running, it will usually result in damage to the piston and the cylinder lining walls.

This is what will happen to the piston when it jammed in the cylinder.

There were very deep scratches on the piston as well as on the cylinder lining. The piston rings were also stuck tight. When this happens, there will be loss in compression resulting in lost of power, and engine oil will get into the combustion chamber resulting in excessive white smoke.

I'm not sure whether the consequences of overheating will cause the valve to break over time but coincidentally the valve which was broken was the valve for the damaged piston and cylinder too.

There was another piston with a rough top surface. So I decided to change this one too.

This is the new exhaust piston/cylinder and the exhaust valve.

It is obvious from the photo above which two pistons and cylinders were replaced.

It took 2 days to assemble the engine. This operation was made much tougher as we were working in very confined space. Sometimes tightening just a single nut may take 15 minutes instead of the usual 1 minute or less.

Another con of working on the engine while on the boat is that you will definitely dirty the boat with your greasy hands and feet. It was an extremely time consuming task to clean the white boat and some of the stains had already become permanent.

No comments:

Post a Comment