There were many issues with my engines during the sea trials and it took more than a month of sea trials before my boat was ready to sail back to Singapore.

This was how the boat was tied to a buoy at the yard.

Every time whenever we wanted to for a sea trial, we would have to roll a small sampan from shore to reach the boat in the middle of the river.

You can see that there is no engine on the sampan, so we would have to exercise our arms everytime before a sea trial. It could get very tiring sometimes when the current was strong.

After we rowed across, we would tie the sampan to the buoy.

And when the tide was high, you would need to do something like this...

Here are the issues during the sea trials:

1) Overheating

There were a couple of reasons which caused the engine to overheat and we had to solve them one by one.

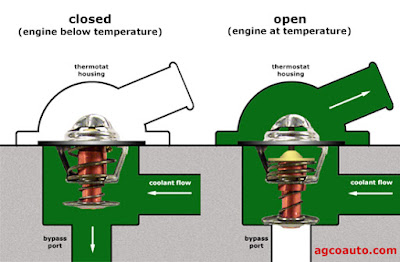

- Insufficient water flow through the thermostat.

Since the engine is old, the water pump is not as strong as before. Instead of changing the water pump, alternatively we can drill holes in the thermostat to allow more water flow so that water will flow through the thermostat even when it is closed. This effectively cooled down the engine significantly.

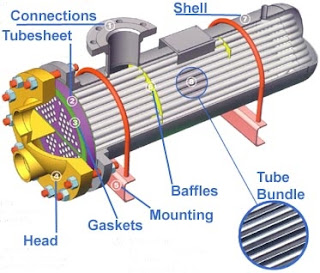

- Leakage of fresh water to sea water through the heat exchanger.

Corrosion within the heat exchanger had caused fresh water to leak from the tube bundle into the sea water compartment shell. This resulted in loss of fresh water (coolant) after running awhile and eventually caused the engine to overheat when the water level went below certain level. The heat exchanger was replaced with another used one.

2) Improper installation

The turbocharger fan was not installed properly and broke into pieces during sea trial. The fan could be replaced however we were not sure whether the broken pieces would go into other engine parts and cause more damages. I just had to keep my finger crossed on this.

3) Trim tab relay damaged

I was not sure whether this was caused by the engine installation but coincidentally the relay was not working and it delayed the progress of the sea trials. It took us a long time to find out that the fault was in the relay.

4) Unsuitable propellers

I had adjusted the pitch of the propellers too high, from 18 to 21. This was partially due to miscommunication. The pitch imprinted on the propellers is 19, so I told the technician to increase 2 pitches to 21. However the pitch was actually 18 because the previous owner had modified the props before. The technican still went ahead to increase the pitch to 21 knowing that the original pitch was 18 instead of 19. This increment of 3 pitches was too much for my engine to handle, which resulted in black smoke during the sea trials. In the end I had to reduce the pitch down to 19. This was another time consuming process as the boat had to be out of the water for the removal and installation of the propellers.

5) Aftermath of overheating

We had lost count on the number of times that the engines got overheated during the sea trials. But it was one incident that was more critical. The starboard engine suddenly stopped running when it got overheated. After the engine cooled down, it started running again, but internal damage was already done. I was not aware of the seriousness of the damage then. It was until when I was back in Singapore that I felt the aftermath. I shall cover this in my future post.

Though plague with all these problems, we find consolation in the peaceful and scenic surroundings during the sea trials...

No comments:

Post a Comment