Putting the engine back in one piece is one thing. But to make sure that it had been assembled properly is another. After the operation of changing the pistons/cylinders and broken valve, there were all sorts of leaks in many areas...

1) Coolant leaks

The coolant was leaking from the heat exchanger plug.

Notice the cracks around the plug.

So it was not just simply changing of the plug. I had to take the whole heat exchanger out for brazing.

The welding looked very ugly, like some kind of disease. So I gave it a new coat.

Now it looks like new. After I installed the heat exchanger back through this limited access space, the coolant started to leak from another spot.

The expansion tank hose started to leak.

There was a crack at the joint between the big hose and the small hose.

And there was also a crack at the hose connection part.

After I replaced the hose. Another part started to leak!!!

This time it took me much longer time to find out where the leak was. I had to remove the compressor and run the engine to find out this leak location.

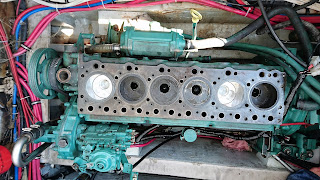

The leak was from the cylinder head gasket! It was this particular rusty coolant hole that leaked. You have to be very observant to notice the slight dent in the gasket which caused the leak.

So we had to dismantle everything again... to change the head gasket (the LONG list of parts to be removed in order to access the gasket is in my previous post "

Engine 101"). And this time, we sprayed copper gasket spray on the new gasket before covering it back.

After finally resolving all the coolant leaks, other types of leaks started to appear.

2) Engine Oil leak

Engine oil was leaking from the pipe leading to the turbocharger.

The rectification for this was relative easy - simply by replacing the gaskets.

3) Diesel leak

This is not that significant but I try to make my engines as leak free as possible. There were various leaks from the diesel delivery pipes and connections.

And sometimes tightening it was just not enough. We have to bend the pipes so that that connections can fit perfectly or under worse case scenario, introduce additional copper washer.

External diesel leak was not as critical compared to internal leaks because if there is an internal diesel leak, the diesel will mix with the engine oil, making the engine oil less viscous. So if you have your engine oil pressure meter readings that look something like this (one high and one low), and you have increasing engine oil reading from the dip stick, the cause might be a diesel leak.

There are a few locations that diesel can find their way to mix with engine oil. For my case, the leak was from the fuel injection pump into the engine body. It is not easy to repair injection pumps, so I took it to an injection pump specialist to replace the seal and bushing.

One important thing to take note during installing the fuel injection pump. There is a timing gear for the pump, hence there is only one orientation that the pump can be installed back.

The four nuts seemed so easy to install but in fact they were not! The spacing between all four nuts varies slightly. That means you can only turn the injection pump in a specific configuration so that all four holes can match.

4) Steering Fluid leak

The cylinder seals for the hydraulic steering was damaged. Hydraulic oil was seen flowing out from the end of the piston.

So I had to remove the whole cylinder, dismantled it and replaced the seals. This is considered an easy job compared to dismantling the engine.

5) Seawater leak

The plug at the oil cooler was badly corroded and sea water started to gush out.

Notice that the mechanic just used some common tap plug to plug the oil cooler hole. It is just a matter of time before it fails. So I replaced the plug with a stainless steel one.

Basically whatever fluid that flows in the boat, it leaked. Since it was a hassle to always have to wait for the mechanic to come from Malaysia, I did all these together with the help from my father - a process which involved lots of sweat and blood.